SiC at its best! Performance & efficiency tested.

PERFORMANCE

Evaluating semiconductor power modules requires different types of test, such as static testing to determine conduction loss as well as dynamic testing for switching loss examination. In order to determine a power module’s performance, Leadrive has developed a fully automated high-precision & high-speed dynamic test platform, designed to complete thousands of test points with ease and speed. Comparing our in-house developed SiC power module with a well-known IGBT power module, our tests showed that the dynamic performance of our SiC power module surpassed the one of the IGBT in many different aspects.

EFFICIENCY

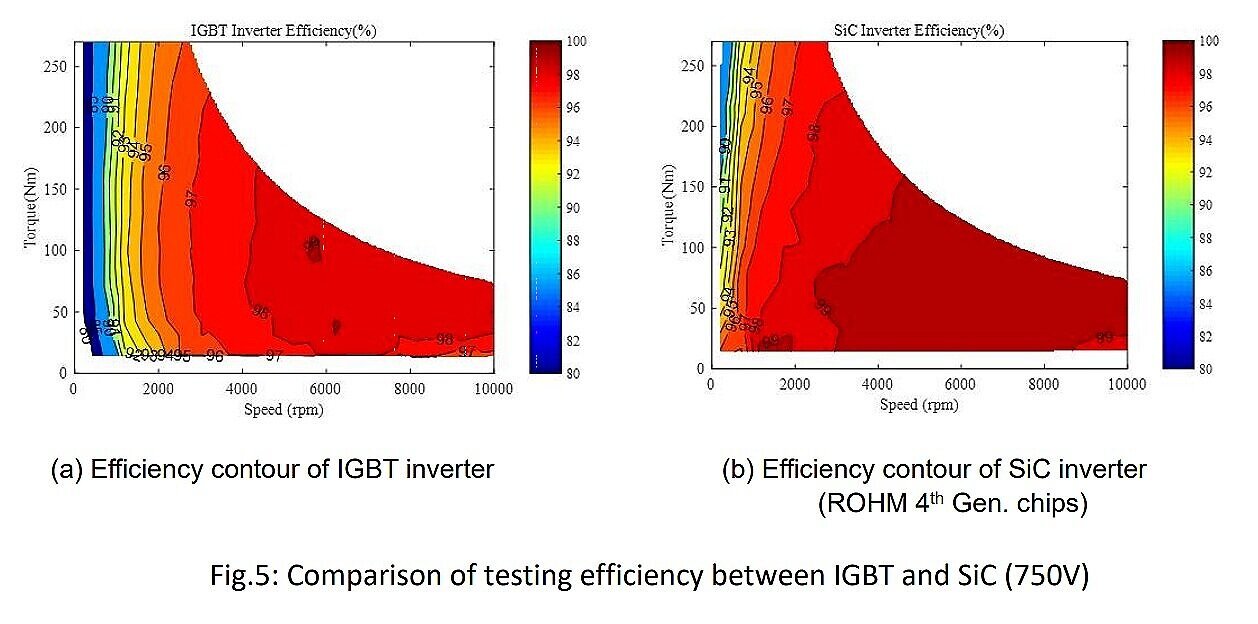

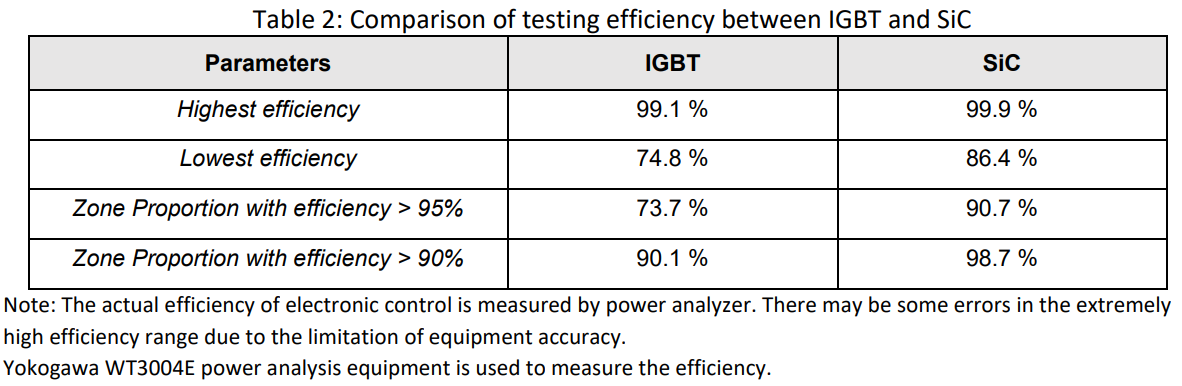

Our SiC power module is incorporating ROHM’s 4th generation 750V SiC chips as well as ROHM’s corresponding isolated gate driver. The efficiency testing of our in-house developed SiC motor control unit (MCU) is performed on a permanent-magnet synchronous motor. Comparing the essential indicators of an IGBT MCU with our SiC MCU, it becomes obvious that not only the high-efficiency range increased but also the peak power output reached higher maximum levels. This derived from the low conduction losses of unipolar power devices, in particular at light load operation. Additionally, the low switching losses of silicon carbide, given the unique wide bandgap material qualities, is another factor.

The test results offer additional notable conclusions: Placing the optimal amount of SiC chips allows to decrease the junction temperature, thus resulting in reduced energy losses. On the opposite, if not enough chips are used, the resulting temperature increase will cause higher energy losses.

For reference and more information, please read the full-length research paper published on the ROHM Semiconductor website: